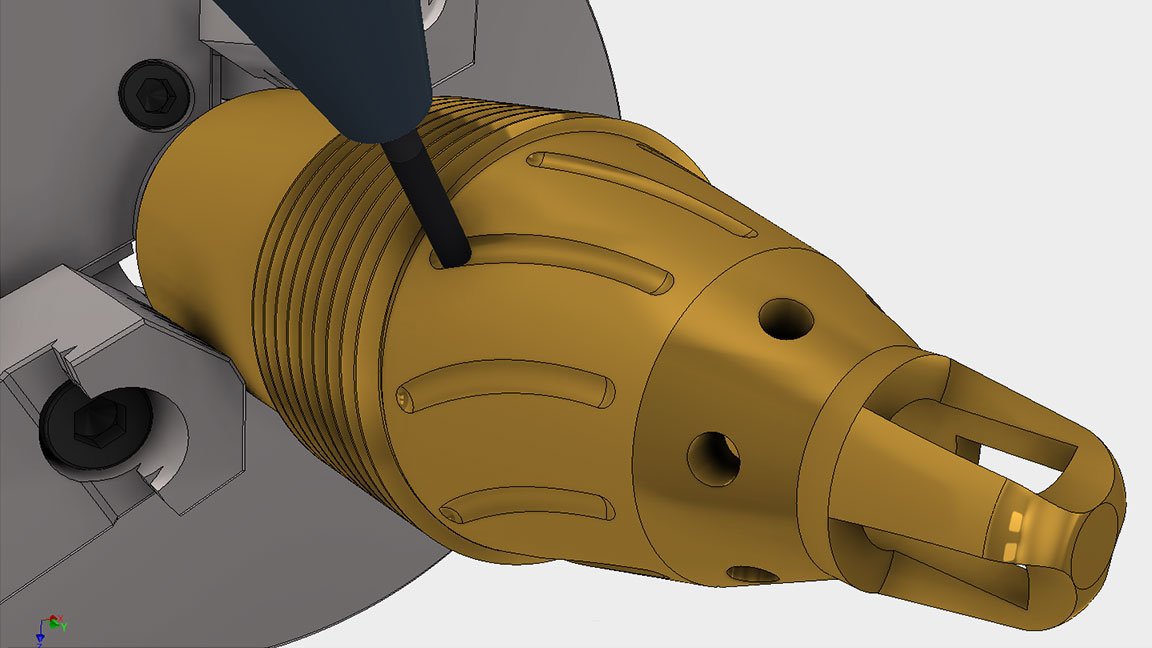

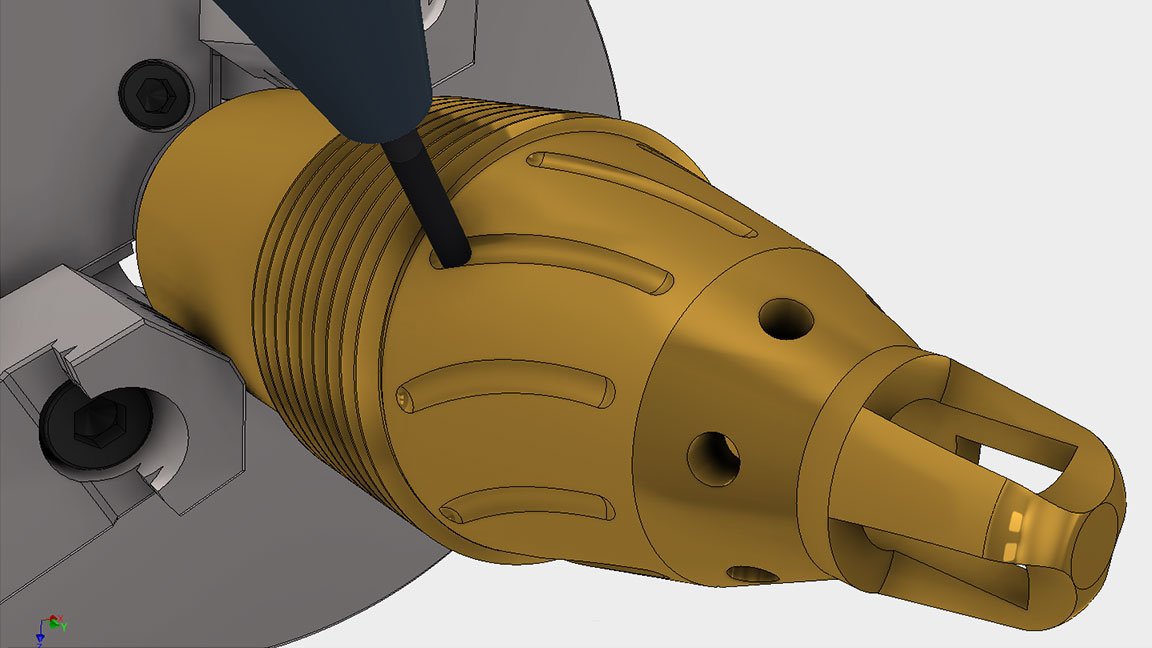

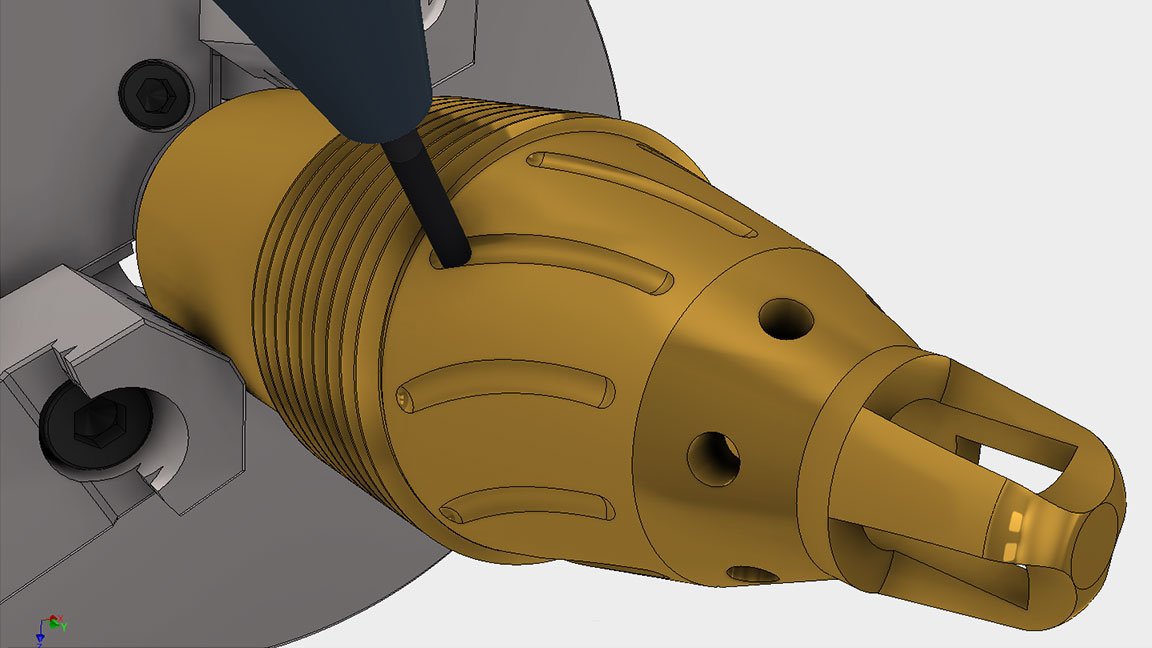

Post-process an Inventor CAM setup to output the CNC machine code required to machine a model.Use the Simulation option to visualize toolpaths.

Create a Facing, 2D Adaptive, 2D Pocket, 2D Contour, and Drilling toolpath using the Inventor CAM interface. Set up machining operations using Inventor CAM. Locate, modify, and create tools in the Tool Library. Use the model orientation commands to pan, zoom, rotate, and look at a model. Navigate the Inventor software interface to locate and execute commands. Through a hands-on, practice-intensive curriculum, students will quickly advance to learning the key skills required to take a 3D model set it up in the CAM environment and assign the toolpaths needed to generate the CNC code required by 2D milling machines. This introductory content was important to include for those users that may not have experience with Inventor but that will need to work with existing models in the CAM environment. Despite this learning guide covering only 2D Milling toolpaths, it will provide an excellent foundation on using the entire interface which remains consistent with the more advanced milling and turning operations.Īutodesk Inventor 2020 Introduction to 2D Milling begins with an introduction to the overall Inventor interface and explains how to manipulate your 3D model to change its orientation and view display. The 2D Milling toolpaths that are covered include Facing, 2D Adaptive, 2D Pocket, 2D Contour, and Drilling. This guide focuses on how to use Inventor CAM to create 2D milling toolpaths. This guide provides students, trainers, and industry professionals with learning content for Inventor CAM. ASCENT is excited to announce the release of a brand new learning guide : Autodesk Inventor 2020 Introduction to 2D Milling.

Create a Facing, 2D Adaptive, 2D Pocket, 2D Contour, and Drilling toolpath using the Inventor CAM interface. Set up machining operations using Inventor CAM. Locate, modify, and create tools in the Tool Library. Use the model orientation commands to pan, zoom, rotate, and look at a model. Navigate the Inventor software interface to locate and execute commands. Through a hands-on, practice-intensive curriculum, students will quickly advance to learning the key skills required to take a 3D model set it up in the CAM environment and assign the toolpaths needed to generate the CNC code required by 2D milling machines. This introductory content was important to include for those users that may not have experience with Inventor but that will need to work with existing models in the CAM environment. Despite this learning guide covering only 2D Milling toolpaths, it will provide an excellent foundation on using the entire interface which remains consistent with the more advanced milling and turning operations.Īutodesk Inventor 2020 Introduction to 2D Milling begins with an introduction to the overall Inventor interface and explains how to manipulate your 3D model to change its orientation and view display. The 2D Milling toolpaths that are covered include Facing, 2D Adaptive, 2D Pocket, 2D Contour, and Drilling. This guide focuses on how to use Inventor CAM to create 2D milling toolpaths. This guide provides students, trainers, and industry professionals with learning content for Inventor CAM. ASCENT is excited to announce the release of a brand new learning guide : Autodesk Inventor 2020 Introduction to 2D Milling.